Energy

INTELIE monitors many floating rigs around the world

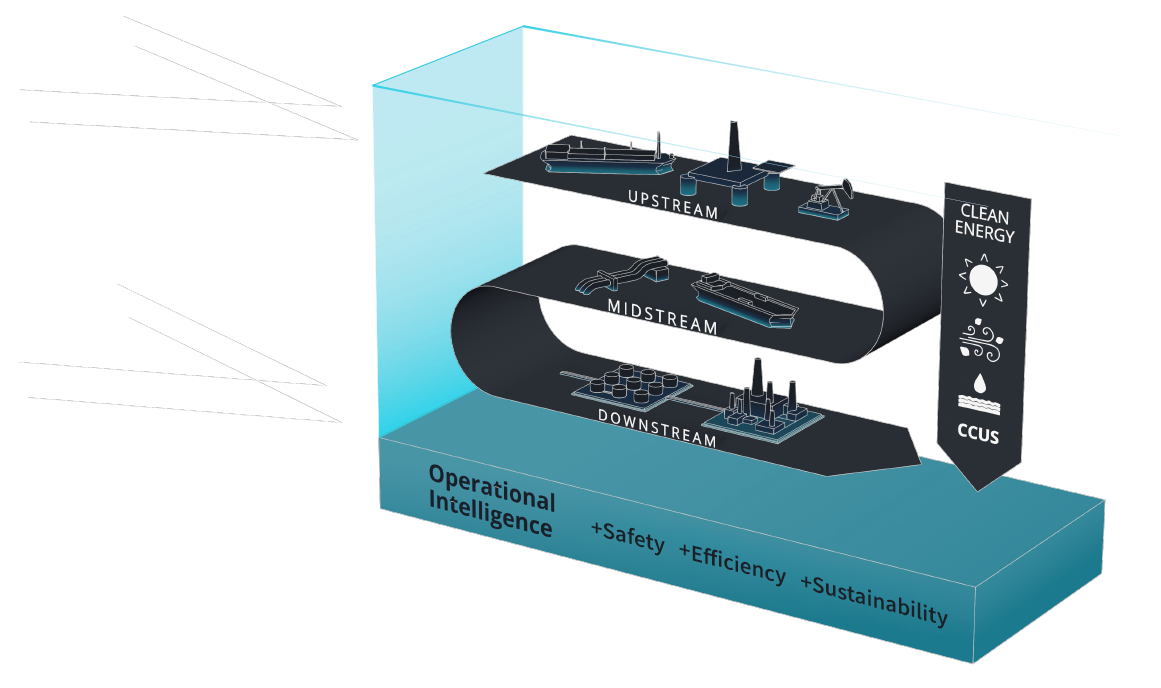

As well as hundreds of onshore and offshore assets. The INTELIE LIVE Operational AI platform has been successfully applied to the Energy industry (upstream, midstream, and downstream) to enable operators (IOC’s, NOC’s, and independents) as well as contractors and service providers across the globe from West Texas shale to deepwater in Brazil or offshore in Asia to transform their operations.

“Finding a partner like Intelie was critical to Ocyan's journey of digital transformation. Being able to monitor and access our operations remotely during the pandemic period was certainly a great advantage for the company."

Energy operational challenges

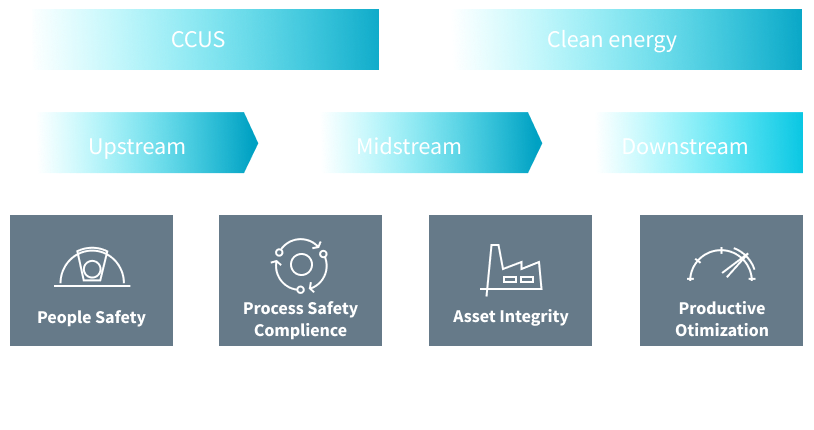

The combination of an accelerating energy transition, loftier ESG goals, and volatile commodity prices are placing greater pressure on the O&G industry for improvement. Simply put, operators must find ways to produce more energy, more efficiently and with lower impact on the planet. This requires a transformation that spans the whole Energy value chain and demands operational systems that are more intelligent and more adaptive. The best thing about it is operational learnings and practices of O&G supply chain are extendable and useful for renewables and CCUS operations.

INTELIE LIVE for Oil and Gas

Automated real-time processes managing corporate risks that threaten safety, compliance, integrity, and performance.

Solutions to fast implement

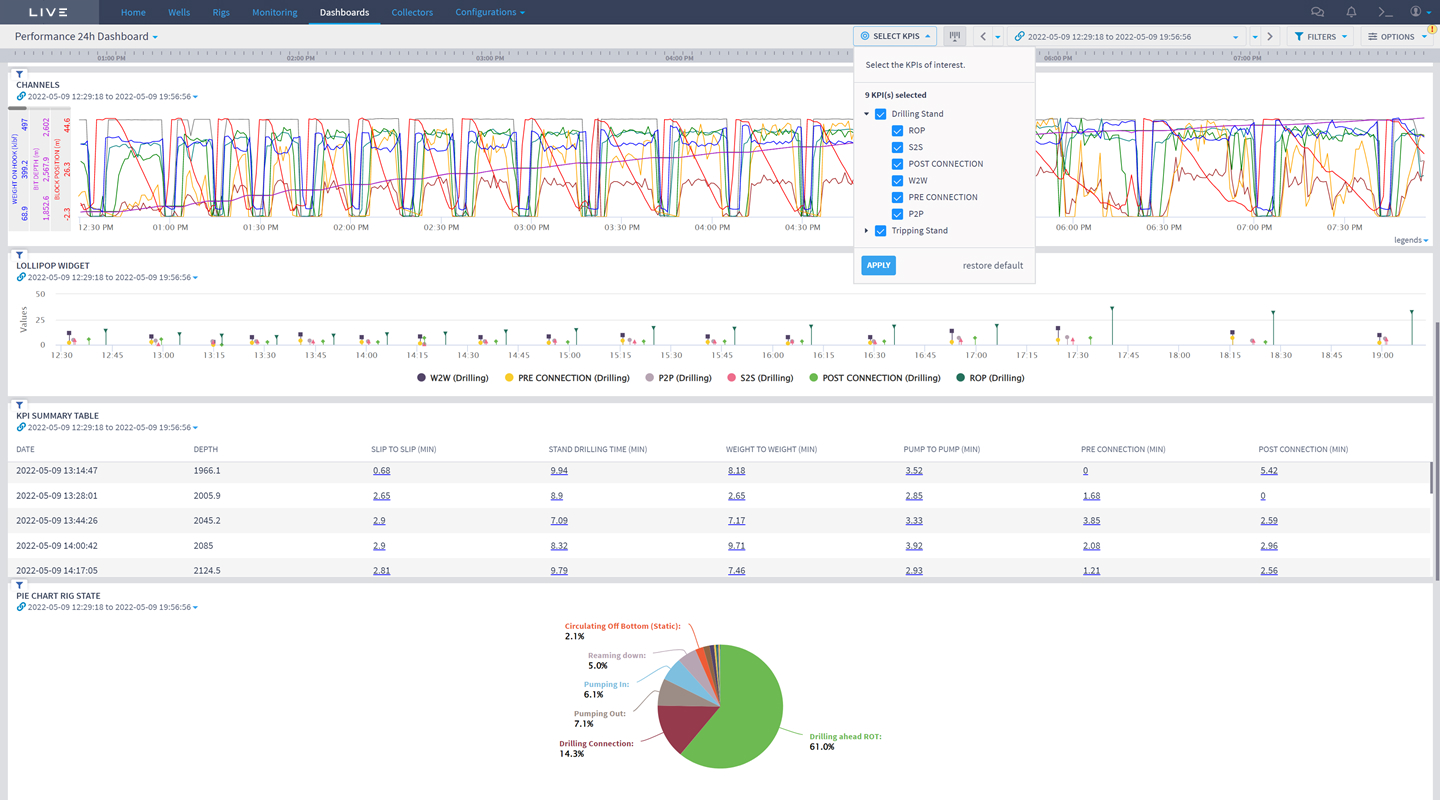

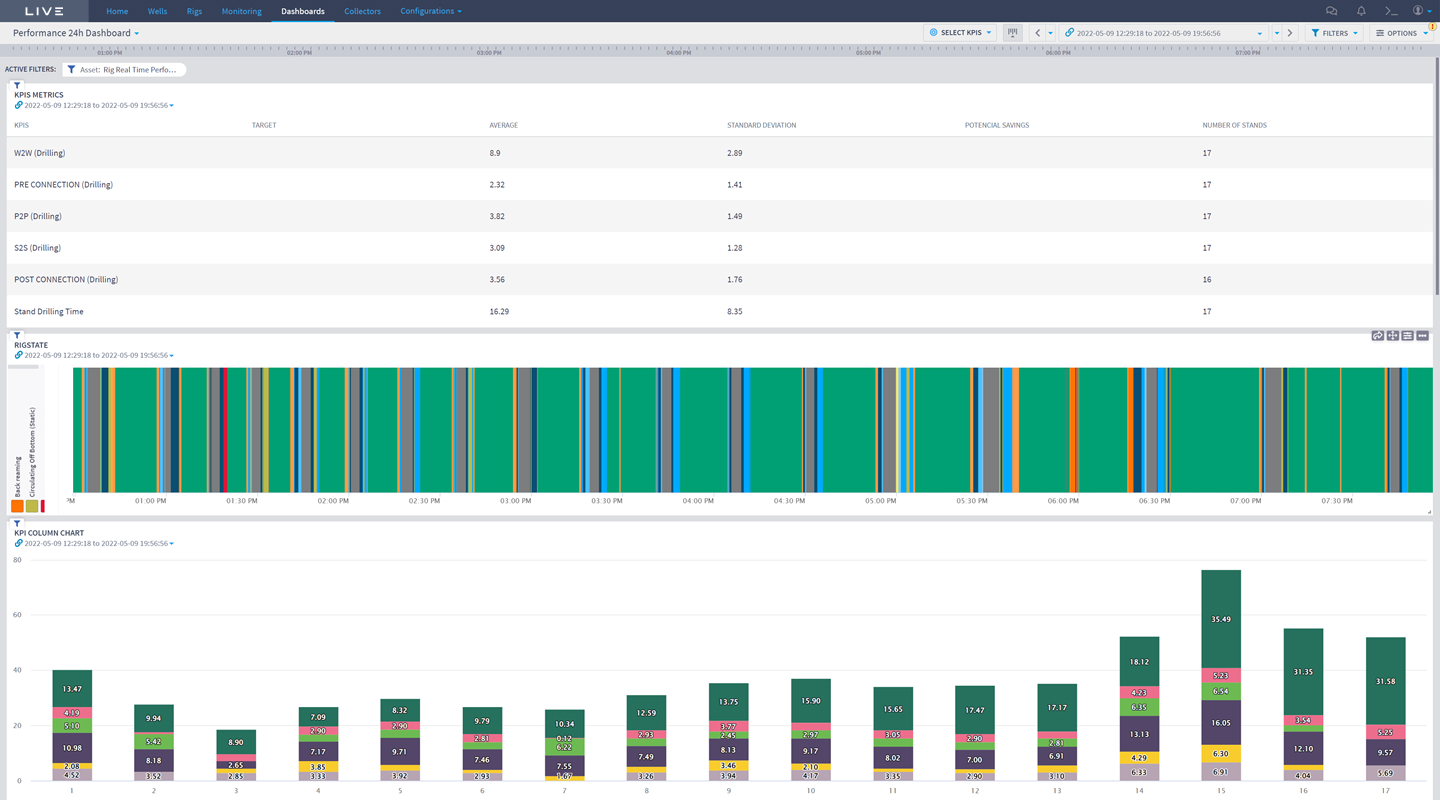

Rigs & Wells Performance

Read the Press Release in PortugueseNow you can measure the performance level of rigs in the construction of oil and gas wells. For both operators and contractors, the app shows the performance of the tubular operation in real-time, making it possible to correct errors and improve performance during the process.

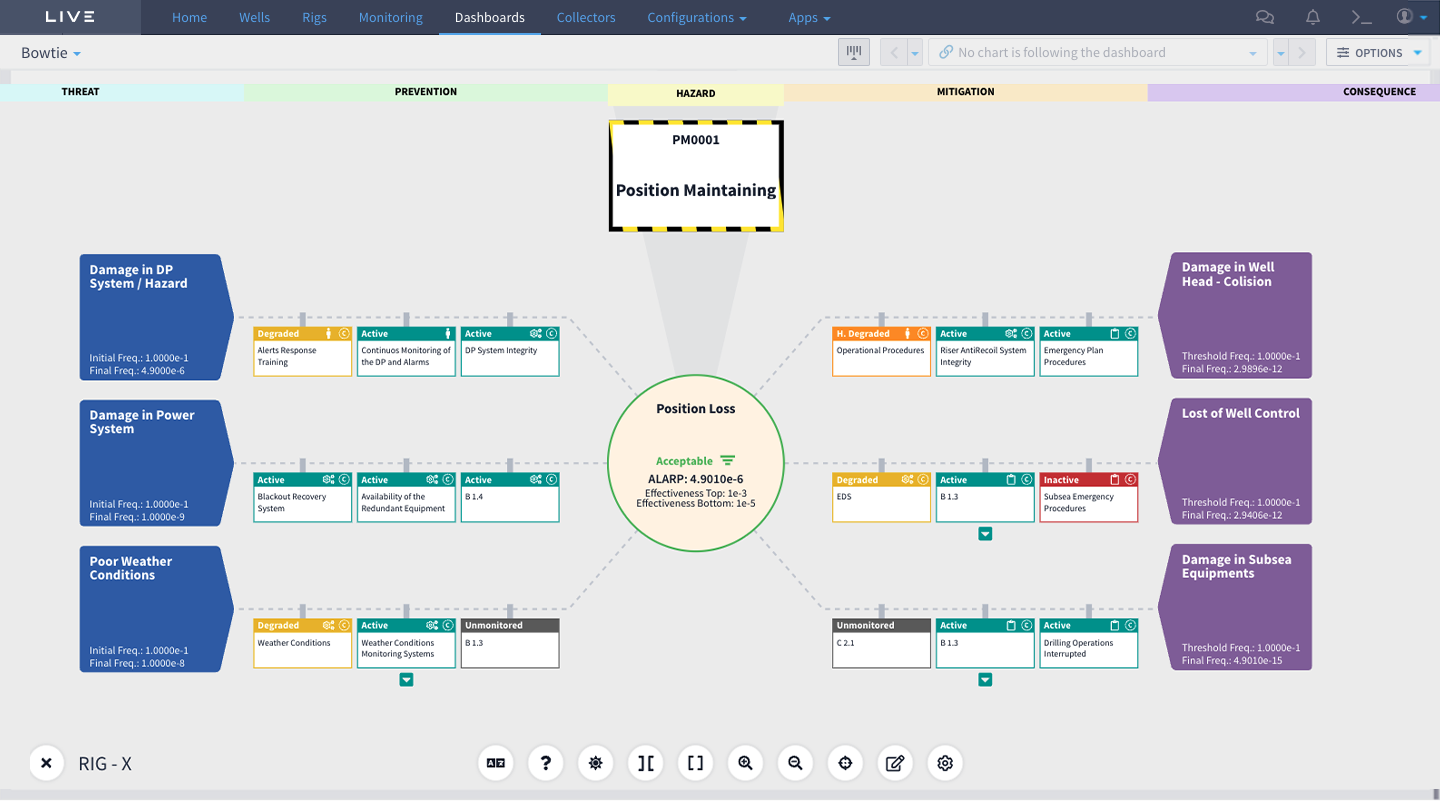

Dynamic Risk Advisor

Watch the DRA videoSafety Integrity Level monitoring in Real-Time. Intelie LIVE Dynamic Risk Advisor provides a dynamic interface that shows the relationship between the hazards, potential adverse consequences and the factors that could cause harm, enabling the current Risk Profile management to comply with Health, Safety and Environment Regulations.

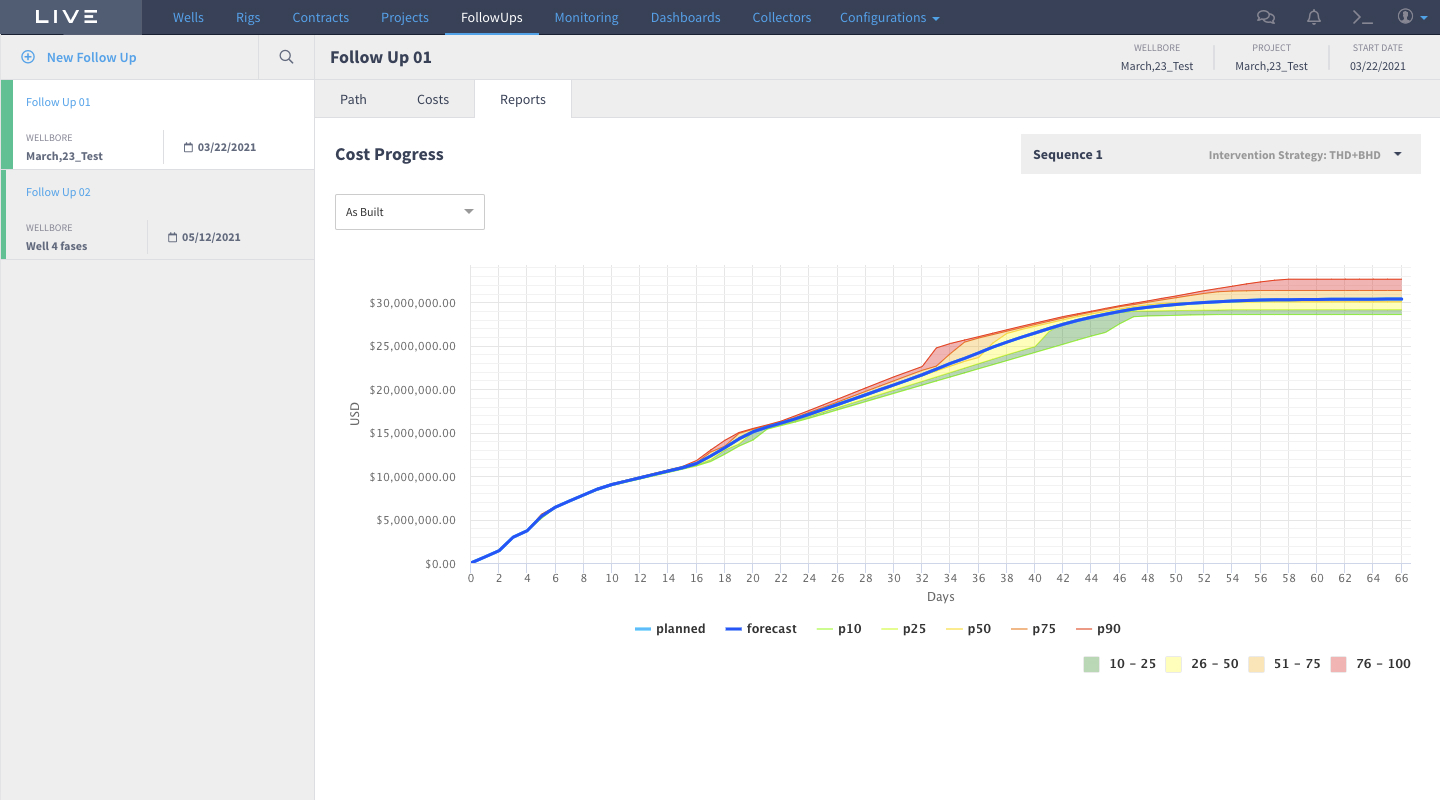

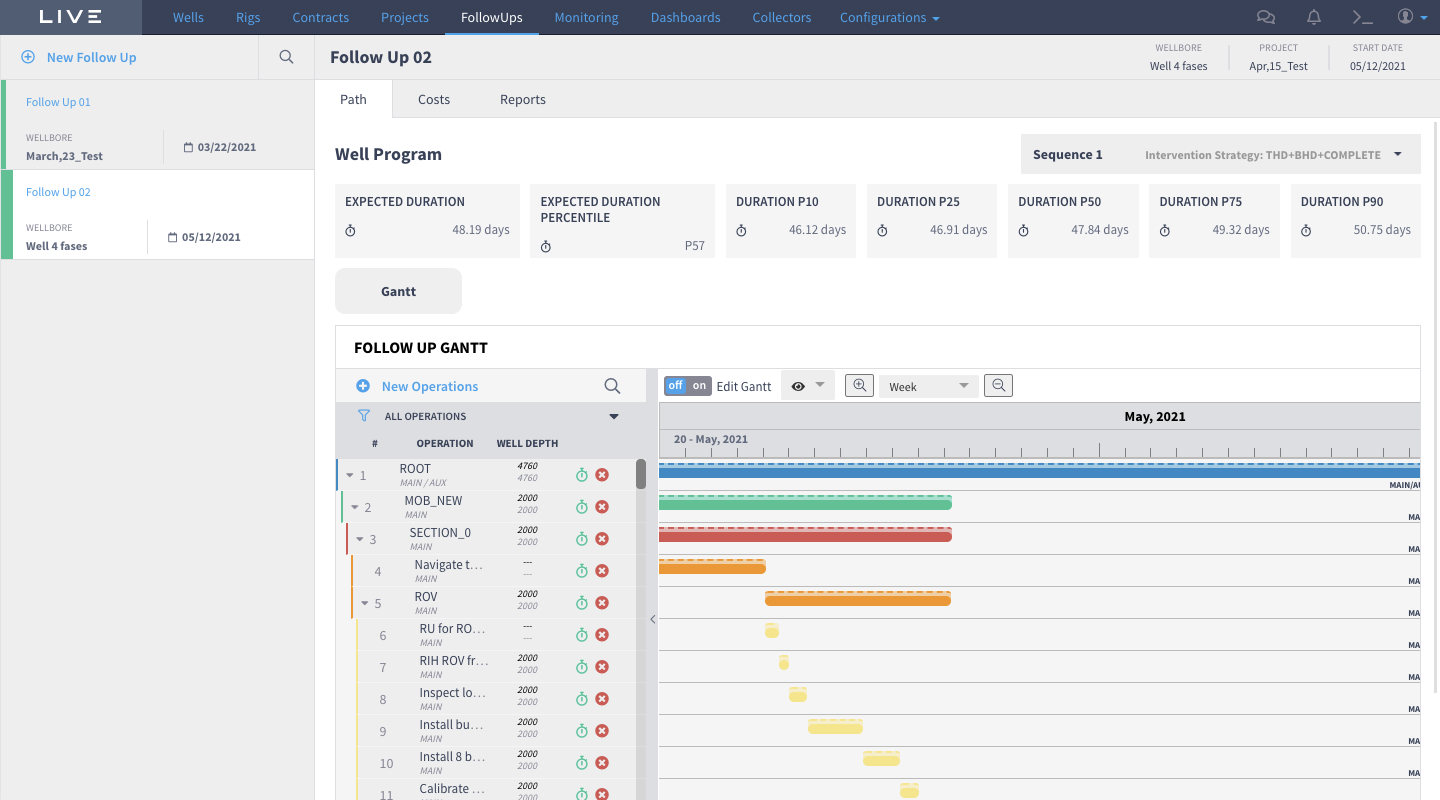

Operational Planning Enhanced

Go beyond your cost estimation and cost tracking. Upgrading your basic offer to include an entirely innovative application that may take the cost, risks, CO2 emissions and other attributes of the well construction to another level of operational planning selection considering multi-attribute objectives. Follow up your attributes daily.

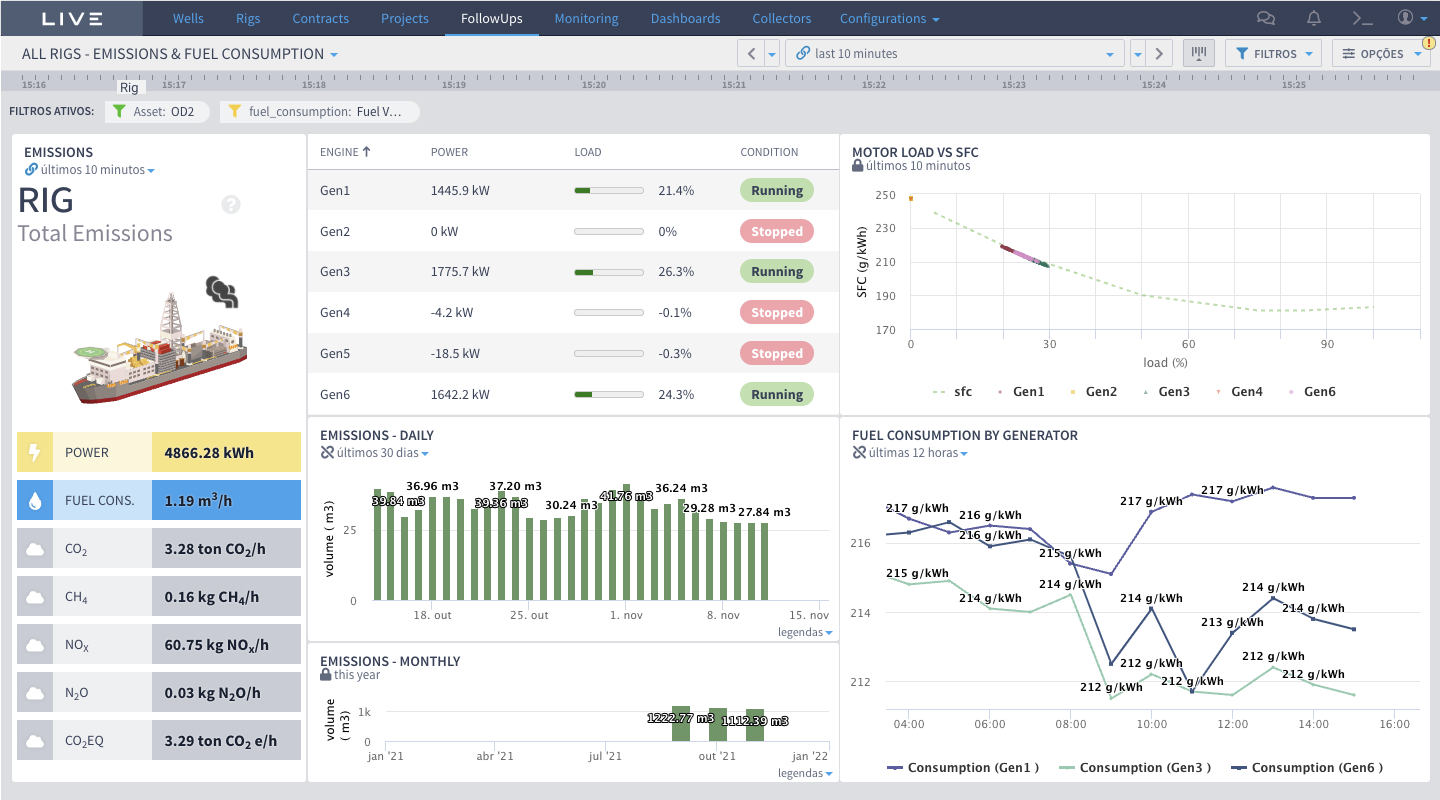

Fuel Consumption & Emissions

Save resources and keep an eye on your sustainable impact. Fuel Consumptions & Emissions Application enables clients to perform real-time fuel and emissions monitoring of any kind of system. Our solution can show a complete set of data from sensors and alerts to enable users to perform preventive maintenance to meet the strict emission standards.

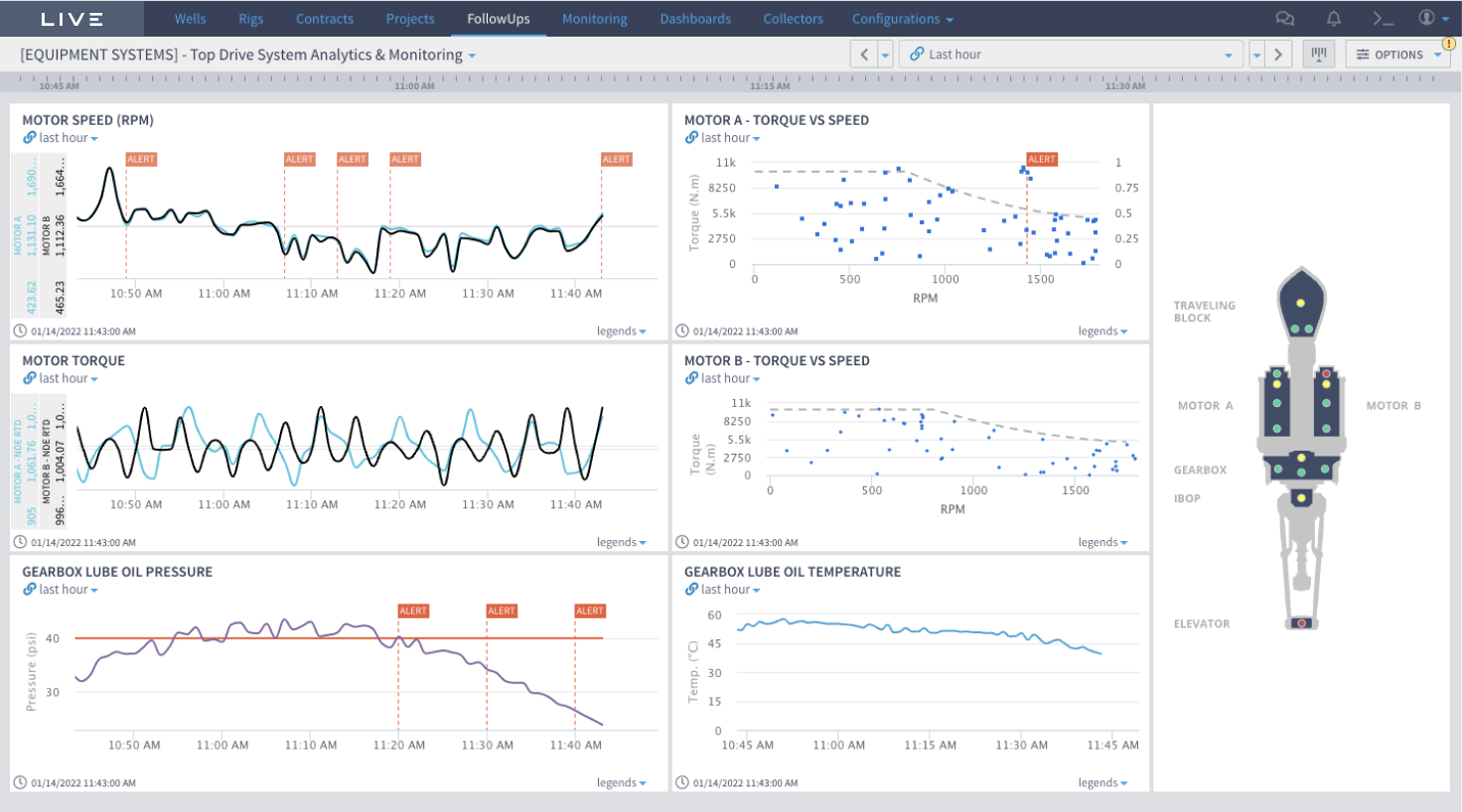

Equipment Health Monitoring

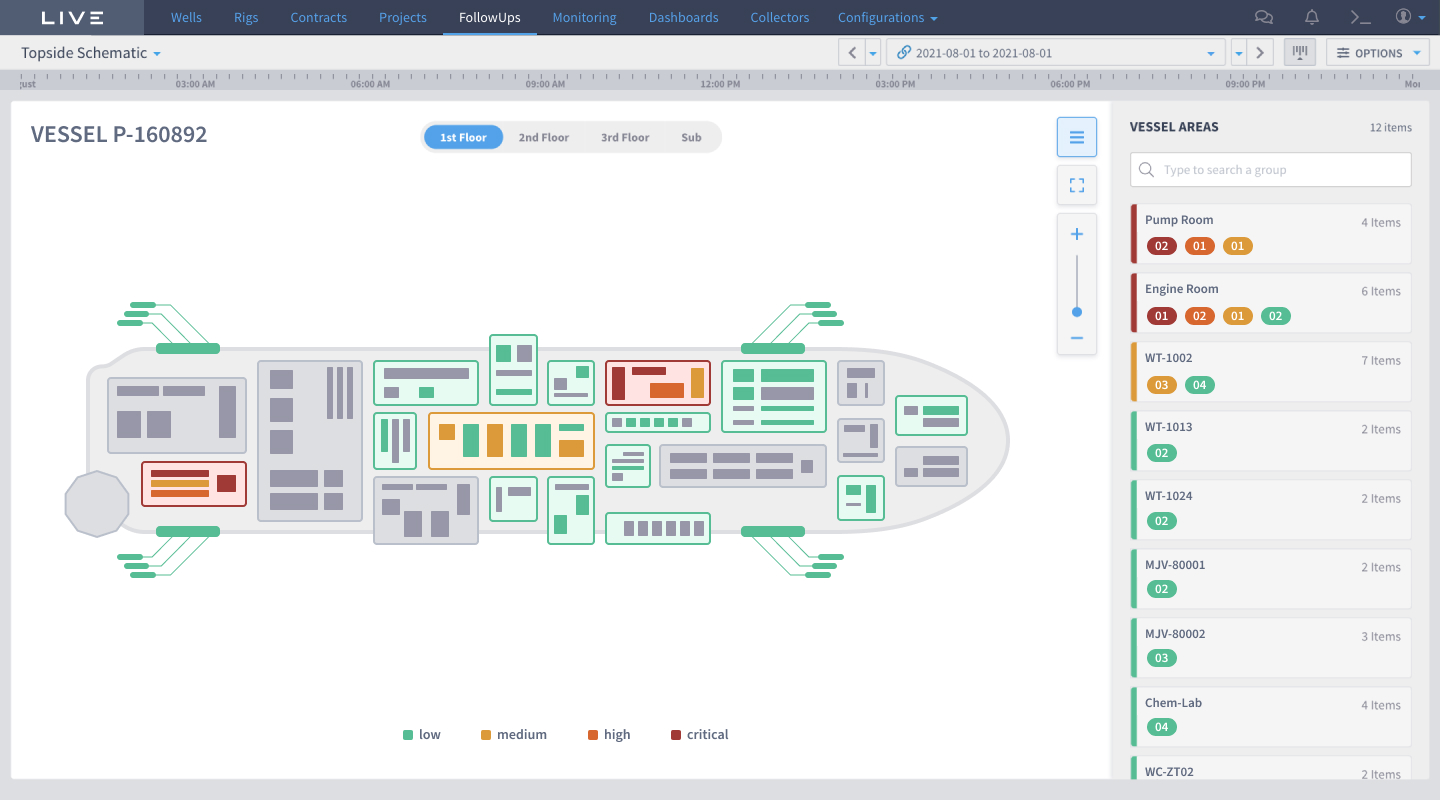

Increase your Uptime and reliability level. LIVE Real-Time Equipment Health monitoring application enables clients to maintain equipment in compliance with the operational limits by alerts/alarms for each component, also it is possible to detect equipment degradation before causing downtime, troubleshooting, and predict its maintenance requirements.

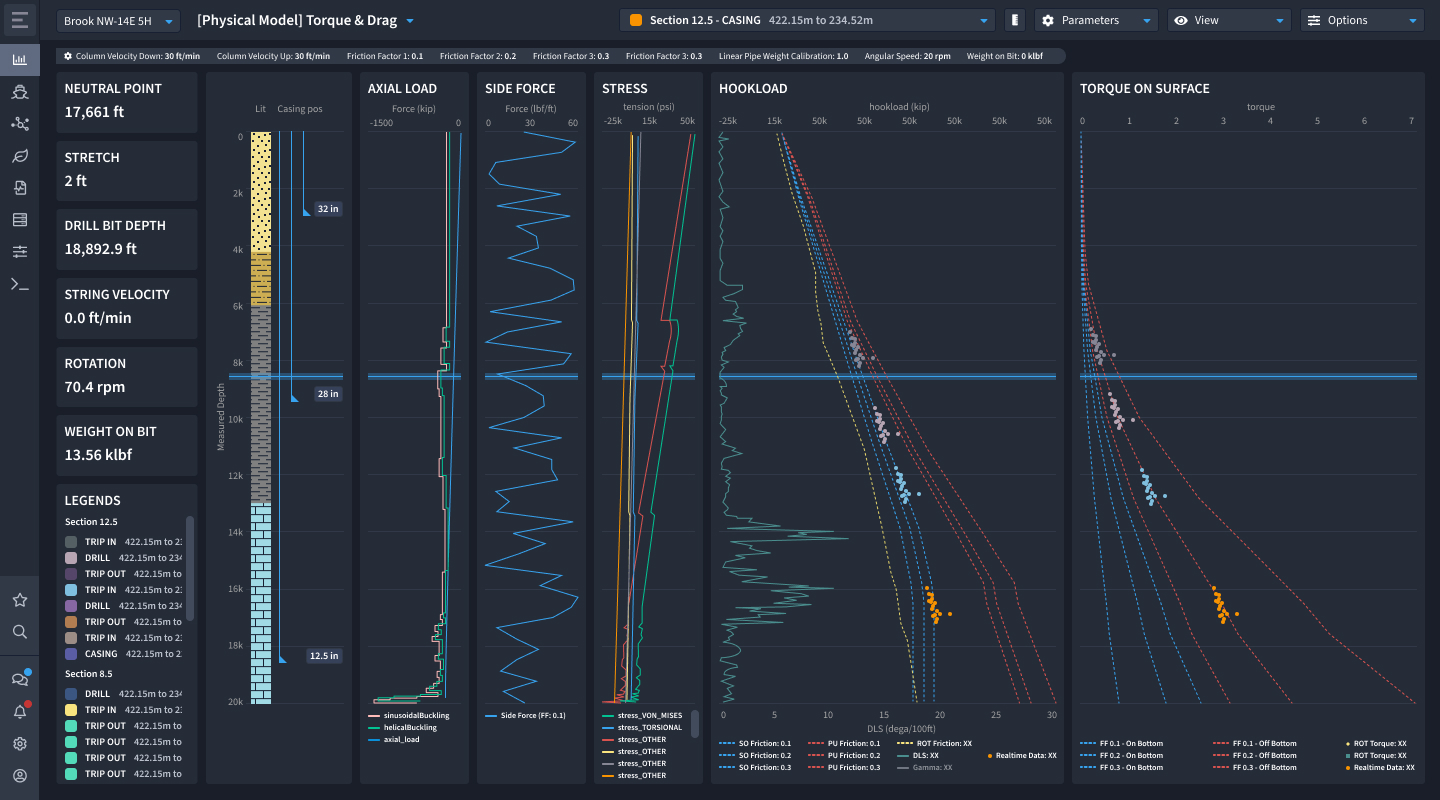

Real-Time Advanced

All you need to guarantee high-level efficiency in your operation. The Real-Time Advanced provides on-demand verification and validation of different pressure tests, engineering simulations based on the Transient Model and better downhole measurements understanding, to provide Real-Time Answers and increasing Process Safety in the Operations.

Real-Time Enhanced

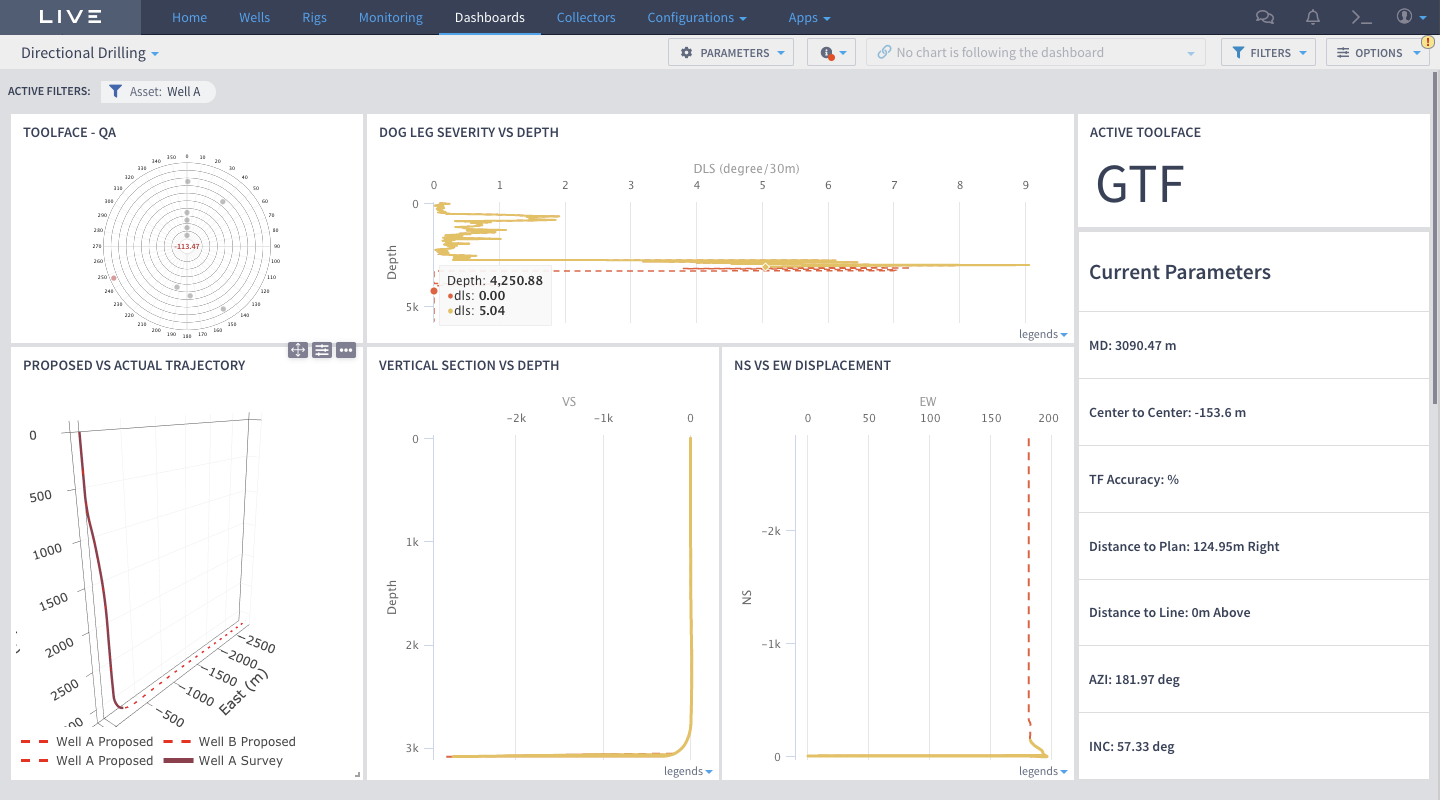

Everything is in one place. The Real-Time Enhanced provides in a unique platform operational contexts based on surface rig sensor data, steady-state simulations engineering analysis and downhole parameters monitoring, allowing your team to focus on Wellbore positioning and what is critical without relying on human interpretation and ensuring a high level of execution.

Real-time Basic

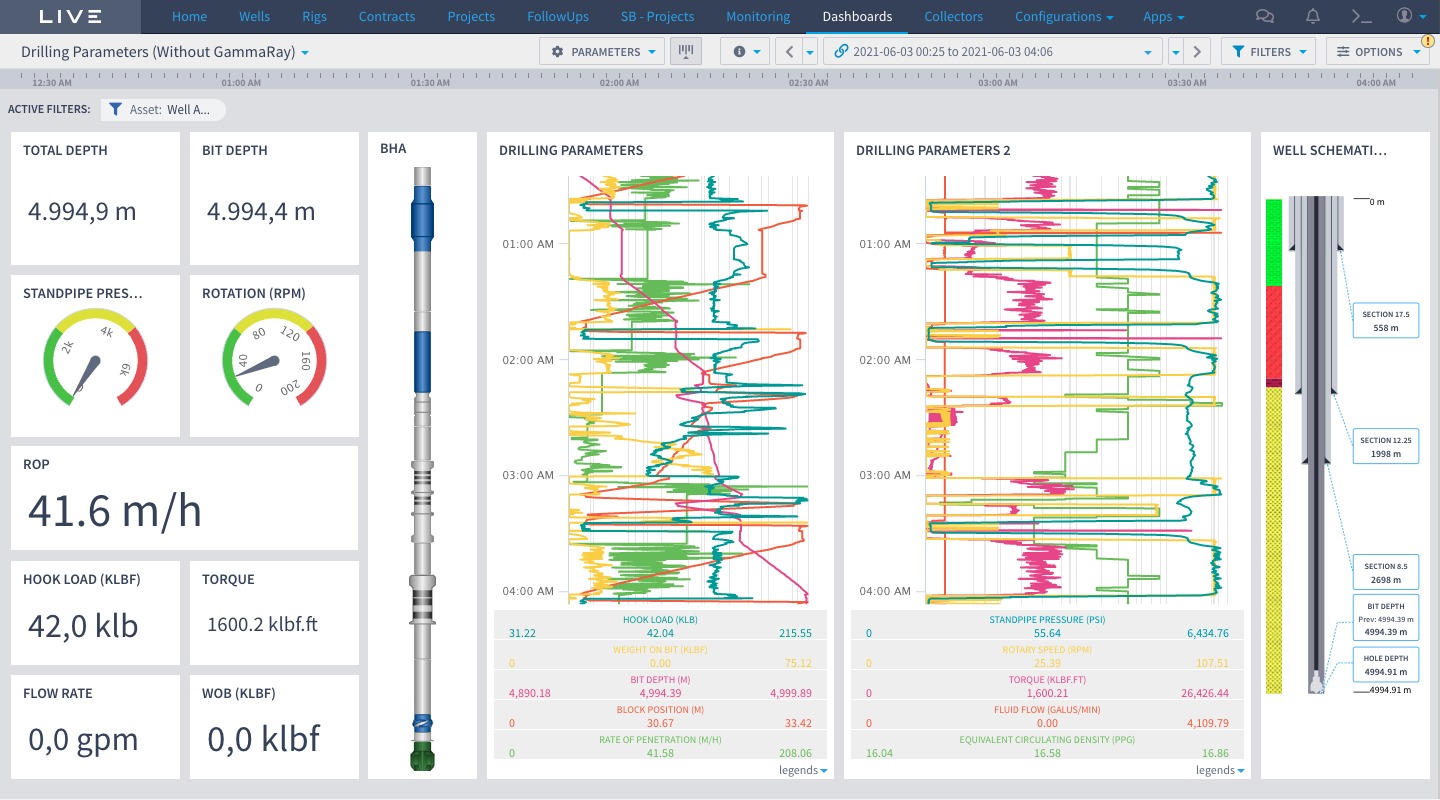

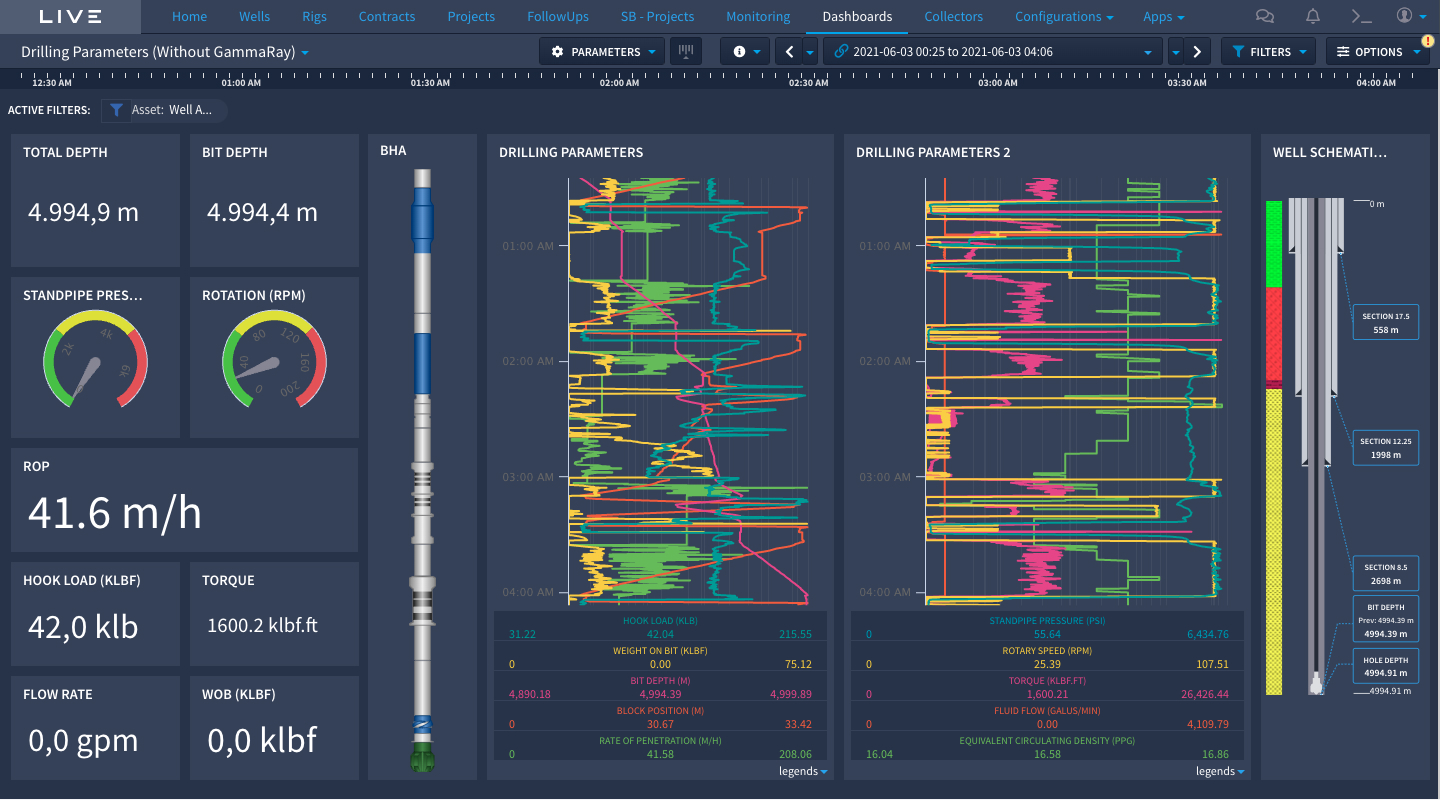

The minimum for your beginning in Operational AI. The Real-Time Basic provides data visualization and surface parameters monitoring for drilling, cementing and mud systems enhancing engineering analysis, enabling your team to improve drilling efficiency and boost operational performance.

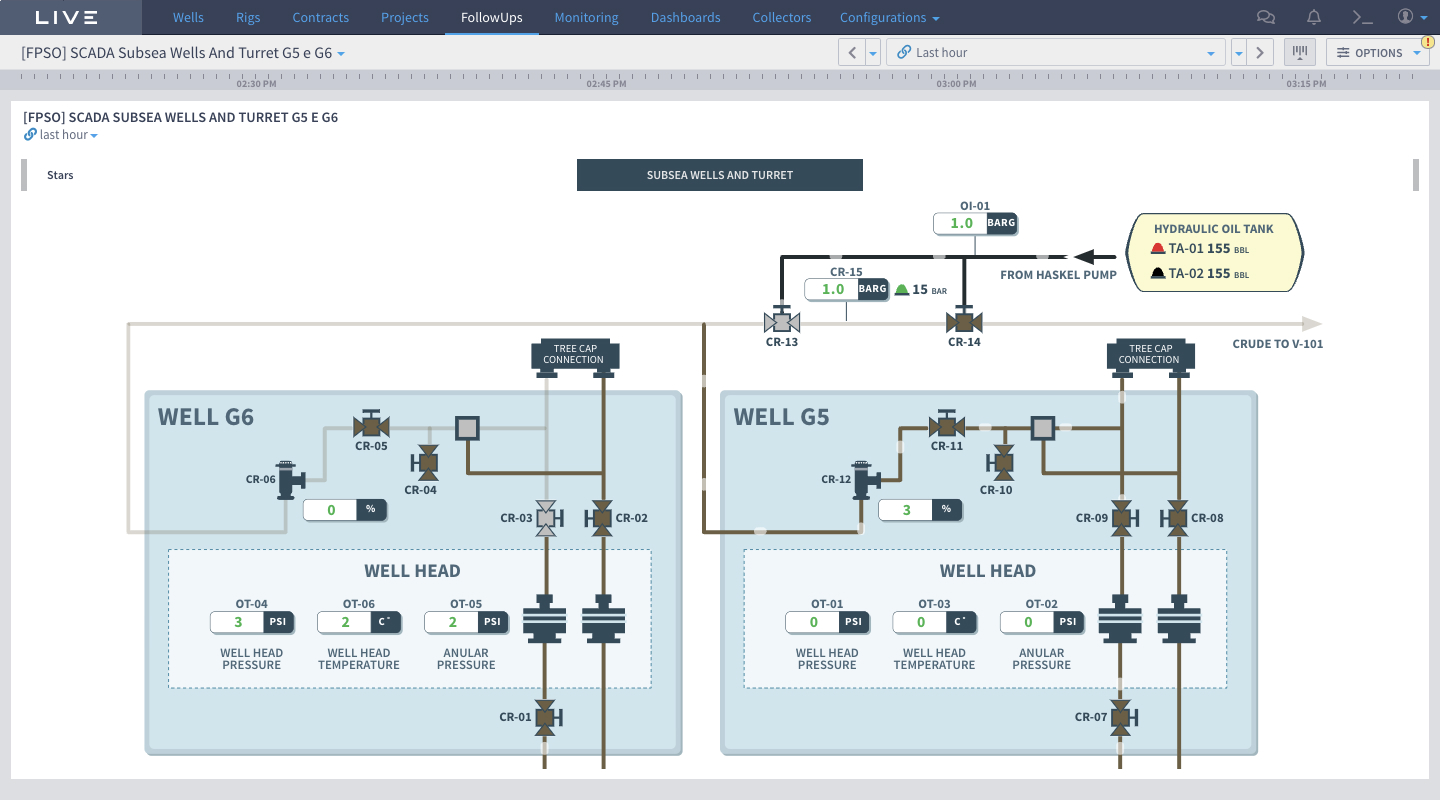

Well Integrity

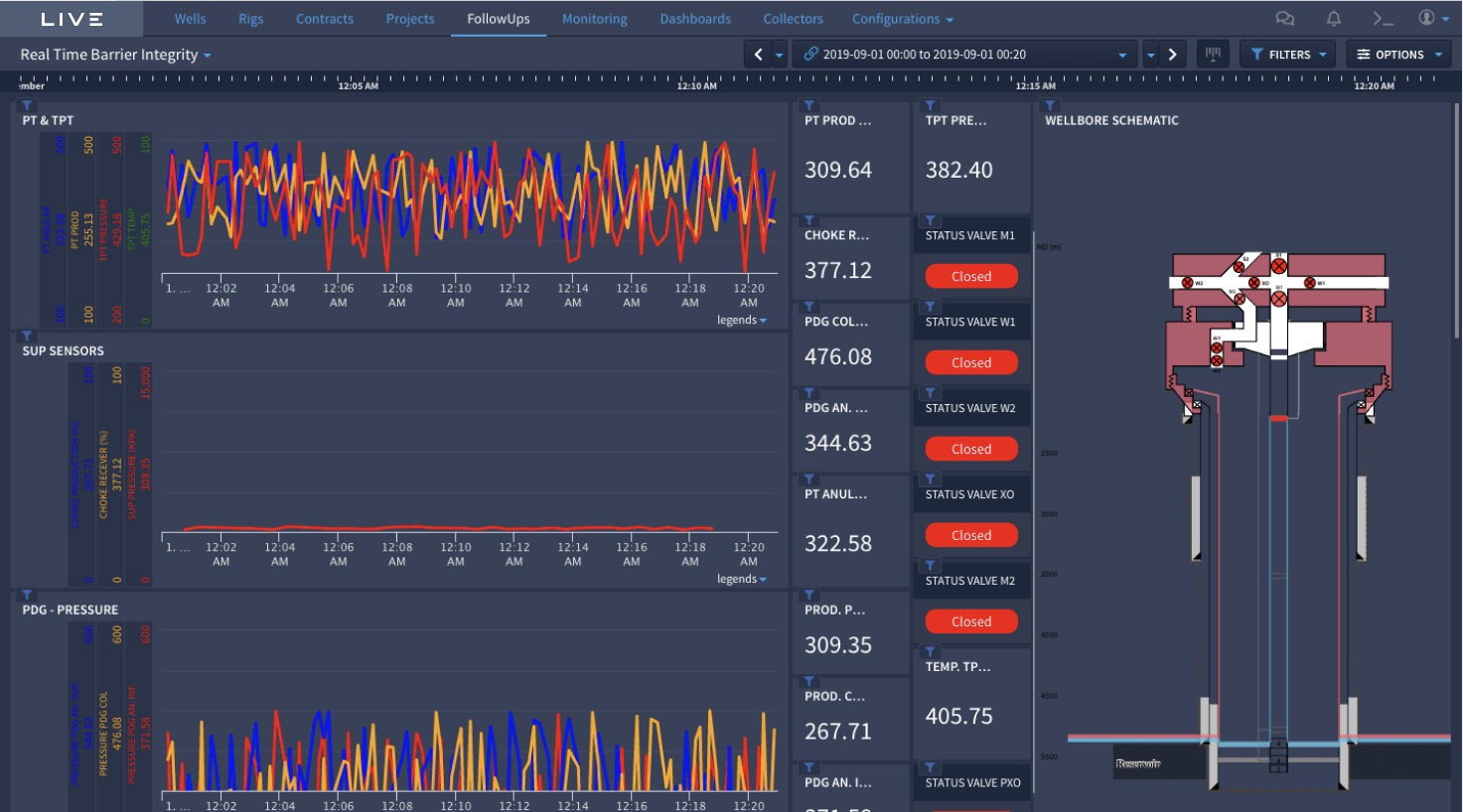

Well Integrity Monitoring in Real-Time. Intelie LIVE provides an easy way to visualize and monitor the current well integrity barriers state. So it is possible to monitor 24/7 your Well Integrity condition and increase your management capabilities by building alerts based on Real-Time events, for example, current well production or well head valves position.

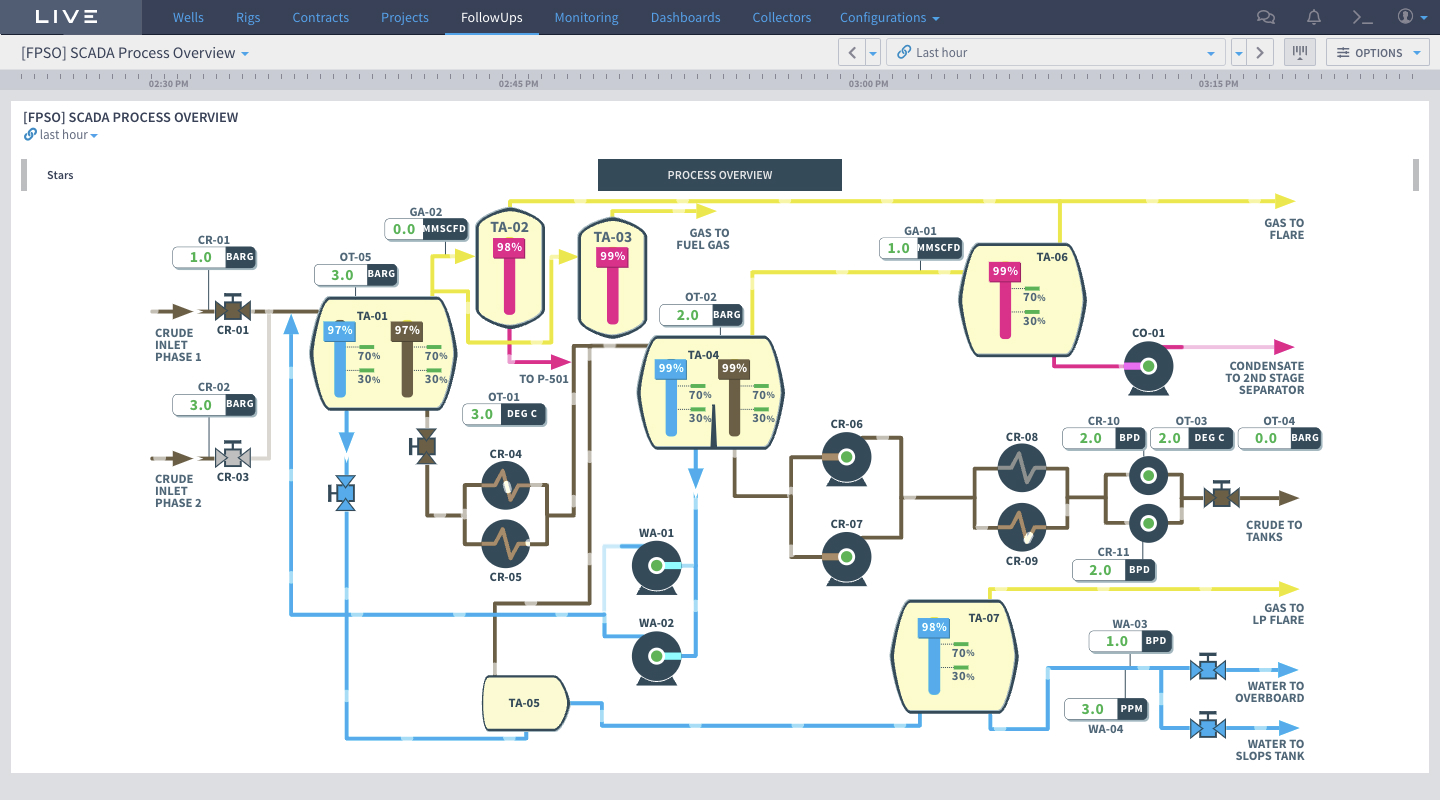

Production Real-Time Advanced

Ultimate intelligence and breakthrough solution in Production, Real-Time Advanced consists in high complexity modeling combined with Machine Learning Technology to improve decision making flow.

Production Real-Time Enhanced

One step further in Production Solution complexity. Production Real-Time Enhanced provides customizations involving integrations with databases relevant to the production balance monitoring and primary oil treatment process, leading to production increase.

Production Real-Time Basic

General Basic Production parameters are available from many Data Sources from the assets, tracking all the information and consolidating it into a single viewing dashboard. All WITSML/ OPC channels are available for visualization, allowing the user to configure channels and alerts/alarm setpoints.

Other cases of energy

We connect, we bring the data, and impossible things happens.